Spacers are fasteners used to connect, separate, or position parts in assemblies.

The hollow body of a spacer is designed to allow the shaft of a screw to pass completely through it before entering the surface material. This forces a gap to be kept between the screw head and the material or component below, while still allowing the fastener to be properly torqued.

They can have a hex or round shape, and are not threaded. They are made of steel, stainless steel, nylon, or aluminum and can have a male or female body style.

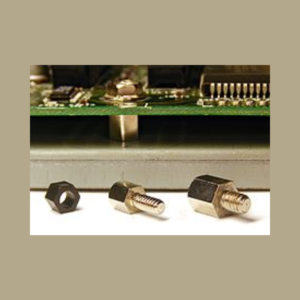

They are generally installed over the top of screws to space out or stack circuit boards or paneling. Spacers can be stacked to cover longer screws if needed. Because they are un-threaded and placed over the top of the screw, there is no torque involved. The spacer can spin or twist without affecting the application in which they are used. Also used to calibrate the height of a sensor or switch, or provide heat or electrical isolation.

Heavier Stainless Steel Spacers are commonly use to install lightweight signs or to separate glass tops on a table.

NYLON SPACERS

Nylon is a lightweight, non-conductive material resistant to impact, wear and abrasion. It is ideal for electrical applications or where corrosion is a concern.

These provide sturdy support, alignment and spacing to a variety of applications such as circuit board assemblies, panels and doors.

In the world of electronic components and electronic hardware, these standoffs are typically used to space circuit boards, panels, doors or gears.

A very useful addition to Drone design.

These offer a smooth surface finish that will not erode the insulation of wires that rub against the nylon spacers.

It is also incredibly lightweight for its overall strength, although it can be prone to shearing in high torque installations. While nylon is highly chemical resistant, it is less suitable for use in damp or humid environments, due to its tendency to absorb moisture over time.

Available in Round Body and Hexagonal Body shapes.

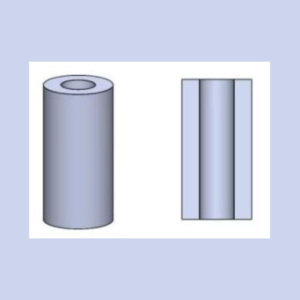

Round Body Spacers

Female unthreaded round circuit board spacers do not have threads and resemble a plain, cylindrical tube.

These Round Unthreaded Spacers can be used for separation and insulation as well.

Available in White or clear as a standard finish.

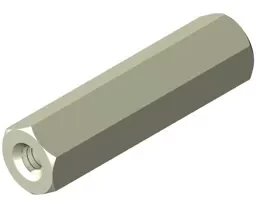

Hex Body Spacers

Female unthreaded hex spacers do not have threads and resemble a plain, hexagonal tube.

The Hexagonal body provides a higher strength and ability to place better on the assembly.

These are available in Black Nylon and provide a sturdy assembly.

SS Round Spacers

A new addition to our range that provides additional options to various product assemblies.

Stainless steel spacers provide high-strength and corrosion resistance, making it a versatile spacer material option.

Made from AISI-303, these are available from 2.5mm hole diameter onward.

These are also useful as sleeves in certain applications that require strength and durability.

Stainless steel tube spacers are often preferred for visible mounting solutions as they remain looking pristine for extended periods.

Aluminium Round Spacers

Another new addition to our range that provides additional options to various product assemblies.

Aluminium spacers are light-weight and corrosion resistant, making it a versatile spacer material option.

Made from Aluminium 6061, these are available from 2mm hole diameter onward.

Aluminium tube spacers are especially suitable for Aerospace applications.