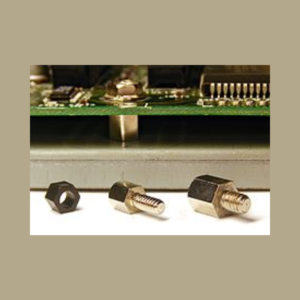

Spacers and Standoffs are two common types of positioning electronic hardware. Look inside an assembled circuit board, and you will be greeted by a bevy of Standoffs and Spacers, because in the world of Electronic Hardware, they are the standard for connecting and mounting circuit boards, panels, doors, and gears providing sturdy support and alignment.

Both are commonly used to properly position parts within an assembly, to reduce component contact, to elevate stacked sections, to ensure enough room for heat to dissipate, and to separate or create space between two objects. These guys are workhorses!

Threaded Standoffs and Spacers

Standoffs are threaded hollow Hex or Round fasteners that separate and position components while also fastening them together. The standoff hardware screws onto bolts or screws by hand. Also called standoff mounts, these fasteners are commonly used to raise one assembly above the other, such as elevating a circuit board above a surface. They can also be used to extend thread options or as an adapter to join male-threaded parts to female-threaded parts (and vice versa).

Types:

1) Through Internal Threaded Standoffs.

These are Female-Female type also known as hex spacers with internal thread or F-F Spacers.

2) Male-Female (E.T.) Standoffs

These are Male-Female type also known as ET spacers or M-F Spacers.

Selection Guide

When designing and choosing a Standoff for your next application, it is easiest to think of standoffs as 3 separate sections; the two threaded ends and the main body. The below guide will help you think through those 3 sections and provide the common information needed for finding the right standoff.

Step 1 – Thread Type

Standoffs are divided into a few different styles and named after the type of threads on each end.

Female-Female Standoffs

These are also referred to as a Threaded Spacer and come with female threads on both ends of the part. This allows for a screw or male standoff to be installed on either side.

In shorter lengths, standoffs will be threaded through the entire part, where longer standoffs are threaded to a minimum thread depth.

Male-Female Standoffs

These have one end with a male thread and the other end has a female thread.

These are excellent for use when stacking circuit boards as each male thread can be installed into the mating part’s female thread.

This quickly reduces the number of fasteners needed in the assembly while also reducing installation time.

Male-Male Standoffs

This has male threads on both ends and are used to connect 2 female threaded components.

These are also commonly utilized as thread adapters to convert a female thread to a male thread.

Male ends can be the same or a different thread for a wider range of applications.

Step 2 – Thread Size

Standoffs are readily available in all common thread sizes, in both inch and metric series. While most commonly found with each end having the same size thread, different thread sizes can be manufactured on specific order.

Step 3 – Body Length

The third part of the standoff once the thread sizes have been determined is the body.

As standoffs are commonly used to separate 2 components, the body of the standoff is what will separate the components.

As each application will require a unique body length, all standoffs come in a wide range of length options.

Parts are machined to a tolerance for a secure and consistent fit.

Custom lengths and tolerances can be manufactured on special order.

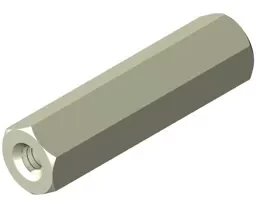

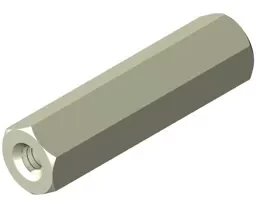

Through Internal Threaded Hex Standoff F-F

A hexagonal, mechanical device which has a partial or complete internal thread, used to hold two components at a given distance from each other.

Advantages – Standoffs are usually chosen over spacers when longer sizes are required. Hex standoffs can be installed with a nut-setter or other wrenching device.

Suitable for using with screws at both ends providing a clean finish.

Materials

Brass

Brass is used in making high-quality standoffs. It is conductive, resists corrosion, and is non-magnetic. It is costlier and heavier than Nylon and is usually plated nickel