Installation is simple, prepare the specified hole and using a flat punch and appropriate anvil, apply a parallel squeezing force to press the part into the hole. When installing in printed circuit board, broaching nuts are suitable for use in non-plated holes only.

-

Pre Applied Patch Screws

Pre applied Thread-Locker Patch Screws

Nylon patch is a pre-applied thread locking coating (typically Nylon), which is fused to internal or external threads of a screw. This patch is dry to the touch and ready for use right out of the box.

Convenience and Reliability:

- Fasteners with pre-applied threadlock are ready for assembly

- Increases productivity on assembly lines with precise thread coverage every time

- 4 years of shelf life under proper storage conditions

- Dry-to-touch, non-tacky finish, non-toxic, and assembler-friendly

- Suitable for temperatures ranging from -58°F to 300°F (-50°C to 150°C)

- Ideal for automated assembly, replacing washer and manual dispensing on production line.

Advantage of a pre applied patch over using thread locking adhesives during assembly.

Perhaps the biggest advantage of preapplying thread-lockers is simply that engineers can be certain the adhesive will actually be on the fastener, in the correct amount and in the correct location. When line personnel apply liquid adhesives during assembly, the process is prone to error. The adhesive may not get dispensed on some fasteners, or it might not be applied in the right spot.

Similarly, with preapplied thread-lockers, engineers can be sure their torque specifications will be met, because the amount of adhesive applied to each fastener will be carefully controlled.

Lastly, preapplying a thread-locker saves assemblers time and money. Liquid adhesives often need a primer to stick to the metal surface of a fastener. The preapplication process eliminates this step. Moreover, every drop of liquid adhesive costs money-and not just for the material itself. Assemblers also need to factor in the cost of waste, dispensing equipment, and cleaning and maintenance.

Nylon patch screw is commonly known as a prevailing torque type self-locking fastener.

-

Pre Applied Patch Screws

Nylon patch is a pre-applied thread locking coating (typically Nylon), which is fused to internal or external threads of a screw. This patch is dry to the touch and ready for use right out of the box.

Convenience and Reliability:

- Fasteners with pre-applied threadlock are ready for assembly

- Increases productivity on assembly lines with precise thread coverage every time

- 4 years of shelf life under proper storage conditions

- Dry-to-touch, non-tacky finish, non-toxic, and assembler-friendly

- Suitable for temperatures ranging from -58°F to 300°F (-50°C to 150°C)

- Ideal for automated assembly, replacing washer and manual dispensing on production line.

Advantage of a pre applied patch over using thread locking adhesives during assembly.

Perhaps the biggest advantage of preapplying thread-lockers is simply that engineers can be certain the adhesive will actually be on the fastener, in the correct amount and in the correct location. When line personnel apply liquid adhesives during assembly, the process is prone to error. The adhesive may not get dispensed on some fasteners, or it might not be applied in the right spot.

Similarly, with preapplied thread-lockers, engineers can be sure their torque specifications will be met, because the amount of adhesive applied to each fastener will be carefully controlled.

Lastly, preapplying a thread-locker saves assemblers time and money. Liquid adhesives often need a primer to stick to the metal surface of a fastener. The preapplication process eliminates this step. Moreover, every drop of liquid adhesive costs money-and not just for the material itself. Assemblers also need to factor in the cost of waste, dispensing equipment, and cleaning and maintenance.

Nylon patch screw is commonly known as a prevailing torque type self-locking fastener.

Available readily in many screw types and sizes.

-

Press Nuts (Broaching Nuts)

Press nuts are used wherever a high degree of joint stability is required in thin-walled sheet metal or plastic parts. They are a very good alternative to nuts that are welded, brazed or welded to the component. Press nut that can obtain a high mounting strength thanks to the knurled portion under the neck.

Portion of the nut under the neck has a unique shape (knurled, grooved) and so a high mounting strength can be obtained.

Post-processing such as rust-proof processing, sputtering treatment for weld-on nuts, etc., not required.Broaching-type fasteners can be used on printed circuit boards as well as on many other types of brittle materials. They are often used on materials composed of glass laminate or epoxy bases. They are also designed for use on materials that are too thin to support adequate threading.

Broaching nuts, also known as PCB nuts due to being commonly applied in printed circuit boards, are designed with a knurled shank that can be pressed into the drilled hole. The shank grips the board with an interference fit by broaching its way into the panel as it is squeezed into the holes.

-

PT Screws CSK Phillips

The reliable Self-Tapping screw for easy fastening into Metal and Plastic.

We have added PT screws – Self-Tapping Screws suitable for both plastics and metal. With a blunt type F end, these are extremely versatile for small and mini assemblies of a number of different materials.

Our screws are made from Stainless Steel AISI-304 Grade to provide a strong corrosion resistant assembly for a long life to your product and are RoHS compliant.

Available in PAN Phillips and CSK Phillips Heads.

-

PT Screws PAN Phillips

The reliable Self-Tapping screw for easy fastening into Metal and Plastic.

We have added PT screws – Self-Tapping Screws suitable for both plastics and metal. With a blunt type F end, these are extremely versatile for small and mini assemblies of a number of different materials.

Our screws are made from Stainless Steel AISI-304 Grade to provide a strong corrosion resistant assembly for a long life to your product and are RoHS compliant.

Available in PAN Phillips and CSK Phillips Heads.

-

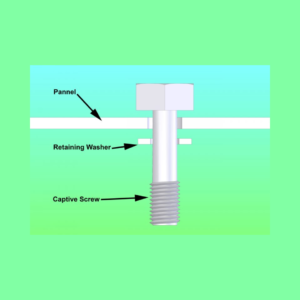

Retaining Washers

Retaining Washers feature internal fins, which grip the thread of a fasteners, creating a self-retaining fastening. Retaining Washers are designed for use with Captive. The combination of Captive Screw and Retaining Washer creates a lightweight and cost-effective locking solution for safety applications.

A Plastic Retaining Washer is primarily used to hold screws and bolts in place during assembly and have a design that grips the outside of screw or bolt shank. Also known as an Anti Loss Washer, they provide insulation, cushioning and spacing. They help insulate fastening assemblies from moisture and electricity.

This washer range includes options with internal and external teeth with a tapered design. The washer slides/assembles on to the screw (or bolt) and is retained by the screw once assembled. The washer cold forms and fully enters the pitch of the screw to provide sealing.

These washers allow for preliminary mounting of the screw (or bolt) before securing with a nut. They are ideal when pre-assembly of the screw and washer is required.

-

Retaining Washers

Retaining Washers feature internal fins, which grip the thread of a fasteners, creating a self-retaining fastening. Retaining Washers are designed for use with Captive. The combination of Captive Screw and Retaining Washer creates a lightweight and cost-effective locking solution for safety applications.

A Plastic Retaining Washer is primarily used to hold screws and bolts in place during assembly and have a design that grips the outside of screw or bolt shank. Also known as an Anti Loss Washer, they provide insulation, cushioning and spacing. They help insulate fastening assemblies from moisture and electricity.

This washer range includes options with internal and external teeth with a tapered design. The washer slides/assembles on to the screw (or bolt) and is retained by the screw once assembled. The washer cold forms and fully enters the pitch of the screw to provide sealing.

These washers allow for preliminary mounting of the screw (or bolt) before securing with a nut. They are ideal when pre-assembly of the screw and washer is required.

Plastic Captive (Retaining) Washers

These Washers have specially configured internal shape designed to grip the outside of the screw shank/threads. These are ideally suited to be used in conjunction with our Captive Screw range. -

Safety & Conical Spring Washers

These are used for locking a device and reducing the vibration. They reduce loosening by preventing unscrewing rotation of the fastening device; locking washers are usually also spring washers.

Washers are available in a wide range such as spring washers, star washers, multi-tooth washers, disc spring washers, wave washers, taper washers, safety washers etc.

Serrated Safety Washers Type S – Schnorr Type

The Safety Washers are of trapezoidal cross section and serrated on both sides. The security is achieved through friction and mechanical locking.Advantages- The cross section ensures locking effect at the outside diameter.

- Due to the closed ring form, high degree of pretensioning is achieved.

- Sliding surfaces allow tightening with damaging the mating surfaces.

- High resistance to vibration due to positive locking of the serrations

- Suitable for a wide range of screw/bolt heads minimizing stocks.

-

Safety & Conical Spring Washers

These are used for locking a device and reducing the vibration. They reduce loosening by preventing unscrewing rotation of the fastening device; locking washers are usually also spring washers.

Washers are available in a wide range such as spring washers, star washers, multi-tooth washers, disc spring washers, wave washers, taper washers, safety washers etc.

Serrated Safety Washers Type S – Schnorr Type

The Safety Washers are of trapezoidal cross section and serrated on both sides. The security is achieved through friction and mechanical locking.Advantages- The cross section ensures locking effect at the outside diameter.

- Due to the closed ring form, high degree of pretensioning is achieved.

- Sliding surfaces allow tightening with damaging the mating surfaces.

- High resistance to vibration due to positive locking of the serrations

- Suitable for a wide range of screw/bolt heads minimizing stocks.

-

SCHS SEMS Screws Allen Cap

SEMS Screws are screws pre-assembled with free spinning washers. The assembly typically contains one plain washer and one split spring washer.

The washers are held in place with the major diameter of the thread being larger than the hole of the washer. This is achieved by inserting the washers before thread rolling.

SEMS screws provide design and manufacturing efficiencies by combining multiple parts, captive washer and screw, into one versatile fastener.

This has many benefits which have revolutionised assembly manufacturing processes, particularly in the Aerospace Avionics sector.

Advantages

– Increased productivity by eliminating hand assembly of washers with the screws.

– Permanent assembly ensuring that the washers are not misplaced.

– Safety for the product as there is no chance of a washer being dropped into the assembly.– One part to inventory, track and assemble.

SEMS screws work well in products with small dimensions, allowing for seamless integration and assembly with a lower risk of error or failure.

-

Self Clinch Standoffs

A Self-Clinching Standoff provides an excellent solution for mounting, spacing and stacking of boards and panels.

They provide strong captivated reusable female threads in a spacer format in thin sheets.

Utilising a hexagon head and a clinch feature, this fastener has excellent torque-out, pull-through and push-out characteristics whilst providing a flush finish on the underside of the panel, requiring minimal surface finishing after installation.

They are installed using a parallel squeezing action, so require access to both sides of the panel.

Ease of assembly and quick removal are major reasons to specify Clinch Standoffs. They satisfy many functional and cosmetic requirements.

Threaded standoff bushes are an effective fastening element that serves as a spacer. A time-saving and simple assembly of workpieces, which have to be arranged at a certain distance from each other or parallel to each other, is made possible by this fastener.

They provide protection for fragile circuitry and electrical connections in printed circuit boards (PCBs) and other electrical assemblies. Self clinching standoffs eliminate the need for loose hardware on aftermarket components.

How Self Clinch Standoffs Work

Attached components are stacked on top of each other or distanced from the framework material by a standoff secured to a thin sheet metal chassis. These metal fasteners ensure safe grounding of electrical components and help reduce or eliminate hardware damage that can occur due to vibration and collision.

-

Self Clinching Blind Fastener

Self Clinching Blind Fasteners are used in applications requiring closed end threads.

Also known as clinching blind press nuts, they provide an excellent design solution for assemblies where there is a desire to protect the contents from foreign matter.

The blind press nuts can be installed into panels as thin 1.0mm. The configuration of the blind press nuts also limit the mating screw’s penetration into the assembly which can prevent any interference within the design.

This feature prevents any contact with the electronic circuitry in the design.

In contrast to the open version, the closed end self clinching nuts offer the advantage of a longer threaded part. The closed shank end seals the thread against external influences such as dirt, oil, moisture and protects against atmospheric corrosion.

In addition, their use is generally more cost-effective than comparable fasteners with similar sealing properties, which, however, require complicated seals and special assembly procedures.

Advantages

- Provide barrier against foreign matter

- Limits screw penetration thereby protecting internal components

- A sealing effect is achieved

These nuts provide a permanent blind thread in thin metal sheets.

The blind press nuts, along with providing the protection of shielding foreign matter from the design, and the mating screws penetration, they also eliminate the possibility of loose hardware.

The blind fastener encapsulates your threads, typically to prevent any foreign material from entering inside. Protrudes on one side of the sheet metal.