-

Ultra Low Profile Metric Screws

Our JCSlim range of Ultra-thin head screw are up to 77% thinner than conventional pan head which makes possible flat external surface and contributes low-profile design and weight saving.

These screws feature a reliable TORX drive that facilitates more reliable installation and support smaller and lighter design.

With the miniaturisation of a large number of products, this has become an invaluable addition to the range of screws. With a flattened fastening face, this supports layers of parts.

The Hexalobular Torx drive provides a slip-less and easy fixing. Stainless Steel provides long life and corrosion resistance.

Applications:

-For flat surface design without head edge

-For smooth appearance designIn installation where the part does not permit deep enough holes to make a countersunk.

The large diameter heads of the low-profile screws have been engineered to spread the load across a wide surface to provide greater holding power in thinner material applications. These offer a sleek, unobtrusive and polished finish for any design.

Saves space and permits flexible design, especially in weight and space sensitive applications such as drones, electric scooters, aerospace and medical equipment.

-

Ultra Low Profile Metric Screws with Narrow Heads

These are available with a special Narrow Head.

The smaller head enables greater weight and space saving.

Available in Stainless Steel AISI 304 grade

Sizes: M2.5 to M4Also available in Black Coated Finish on request

This finish is very useful in reducing light reflection from parts and providing an integrated finish to black coloured products and parts.

These screws have a permanent black colour with exceptional strength and elasticity that does not chip, peel, craze, or rub off and provides good resistance to wear and abrasion.

-

Ultra Low Profile Screws Unified Series

Our JCSlim range of Ultra-thin head screw are up to 77% thinner than conventional pan head which makes possible flat external surface and contributes low-profile design and weight saving.

Usage Guidelines

- Always keep the tightening torque within the recommended torque range. This will prevent screw and joint failure. Consult the product datasheet for details. Using a torque enabled driver is recommended.

- Check tapped hole with thread plug gauge before assembly to ensure perfect installation.

- Use a good quality Hexalobular bit and check that there is no excessive play before applying torque.

-

Ultra Low Profile Wafer Head Laptop Screws

These screws feature a reliable TORX drive that facilitates more reliable installation and support smaller and lighter design.

With the miniaturisation of a large number of products, this has become an invaluable addition to the range of screws. With a flattened fastening face, this supports layers of parts.

The Hexalobular Torx drive provides a slip-less and easy fixing. Stainless Steel provides long life and corrosion resistance.

Applications:

-For flat surface design without head edge

-For smooth appearance designIn installation where the part does not permit deep enough holes to make a countersunk.

The large diameter heads of the low-profile screws have been engineered to spread the load across a wide surface to provide greater holding power in thinner material applications. These offer a sleek, unobtrusive and polished finish for any design.

Saves space and permits flexible design, especially in weight and space sensitive applications such as drones, electric scooters, aerospace and medical equipment.

JCSlim Low Profile Wafer Head Screws

Low profile or Wafer Head screws are often used in laptops and other electronic components.

Made from Steel with a Black Coating, this has many advantages.

- Magnetic to facilitate easy holding to the driver bit.

- Black coated to match with most electronic assemblies and light absorption.

- Low profile head for space and weight saving.

- Lengths as short as 2 mm for an M2 screw available.

- Lengths in decimals also available eg. 2.5, 3.5 etc

Available in Steel BLACK coated.

Sizes: M1.2 to M3This finish is very useful in reducing light reflection from parts and providing an integrated finish to black coloured products and parts.

These screws have a permanent black colour with exceptional strength and elasticity that does not chip, peel, craze, or rub off and provides good resistance to wear and abrasion.

Applications:

- For flat surface design without head edge

- For smooth appearance design

- In installation where the part does not permit deep enough holes to make a countersunk.

-

Unified Series Fasteners

American Standard Unified Threads

A number of Aerospace components have American Standard Threads as standard fitments. To enable this supply chain to function effectively, we have developed and maintain ready stock of a number of ASME/ANSI standard unified thread components.

Available in Stainless Steel AISI-304 and AISI-316 grades.

-

Unthreaded Spacers

Spacers are fasteners used to connect, separate, or position parts in assemblies.

The hollow body of a spacer is designed to allow the shaft of a screw to pass completely through it before entering the surface material. This forces a gap to be kept between the screw head and the material or component below, while still allowing the fastener to be properly torqued.

They can have a hex or round shape, and are not threaded. They are made of steel, stainless steel, nylon, or aluminum and can have a male or female body style.

They are generally installed over the top of screws to space out or stack circuit boards or paneling. Spacers can be stacked to cover longer screws if needed. Because they are un-threaded and placed over the top of the screw, there is no torque involved. The spacer can spin or twist without affecting the application in which they are used. Also used to calibrate the height of a sensor or switch, or provide heat or electrical isolation.

Heavier Stainless Steel Spacers are commonly use to install lightweight signs or to separate glass tops on a table.

NYLON SPACERS

Nylon is a lightweight, non-conductive material resistant to impact, wear and abrasion. It is ideal for electrical applications or where corrosion is a concern.

These provide sturdy support, alignment and spacing to a variety of applications such as circuit board assemblies, panels and doors.

In the world of electronic components and electronic hardware, these standoffs are typically used to space circuit boards, panels, doors or gears.

A very useful addition to Drone design.

These offer a smooth surface finish that will not erode the insulation of wires that rub against the nylon spacers.

It is also incredibly lightweight for its overall strength, although it can be prone to shearing in high torque installations. While nylon is highly chemical resistant, it is less suitable for use in damp or humid environments, due to its tendency to absorb moisture over time.

Available in Round Body and Hexagonal Body shapes.

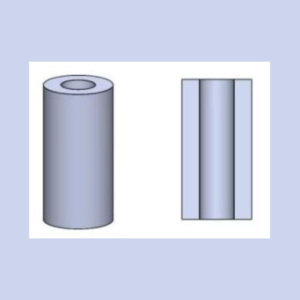

Round Body Spacers

Female unthreaded round circuit board spacers do not have threads and resemble a plain, cylindrical tube.

These Round Unthreaded Spacers can be used for separation and insulation as well.

Available in White or clear as a standard finish.

Hex Body Spacers

Female unthreaded hex spacers do not have threads and resemble a plain, hexagonal tube.

The Hexagonal body provides a higher strength and ability to place better on the assembly.

These are available in Black Nylon and provide a sturdy assembly.

SS Round Spacers

A new addition to our range that provides additional options to various product assemblies.

Stainless steel spacers provide high-strength and corrosion resistance, making it a versatile spacer material option.

Made from AISI-303, these are available from 2.5mm hole diameter onward.

These are also useful as sleeves in certain applications that require strength and durability.

Stainless steel tube spacers are often preferred for visible mounting solutions as they remain looking pristine for extended periods.

Aluminium Round Spacers

Another new addition to our range that provides additional options to various product assemblies.

Aluminium spacers are light-weight and corrosion resistant, making it a versatile spacer material option.

Made from Aluminium 6061, these are available from 2mm hole diameter onward.

Aluminium tube spacers are especially suitable for Aerospace applications.

-

Wafer Head Self Drilling Screws

A Self-Drilling Screw is a Self-Tapping Screw with the added feature of a drill point. The drill point looks a lot like the point of a drill. It will drill a hole and form the mating threads in one operation.

A wafer head is unique.

Materials

Carbon Steel

Stainless Steel AISI-304

Stainless Steel AISI-316

Bi-Metal – SS-304 with Carbon Steel Drill point.

Stainless Steel AISI-410

FINISH/COATING

Zinc Electroplated

Class-3 Coating

Passivated

Wafer Head with Phillips

Truss with Phillips

-

Wedge-Lock Washers

Bolted connections tend to work themselves loose under certain operating conditions. Vibrations cause particular problems as they can overpower the “self-locking effect” of bolted connections. This can lead to functional failure or even lead to the connection coming apart. As it’s not always possible to know what forces are acting on the structure, and as constructional measures cannot be implemented everywhere, securing elements are often used.

One of the few effective securing technologies available is the HEICO-LOCK® wedge locking system, the effectiveness of which has been demonstrated by the latest experimental standards (including DIN 65151, DIN 25201-4, NASM 1312-7).FUNCTIONAL PRINCIPLE

Advantages

Certified system for securing bolts, works at low and high preload levels.

Particularly suitable for dynamic loads – including when using lubricants.

Can be re-used.

Very easy to install and remove (wedge lock washers are supplied as a pre-assembled pair)

Suitable for high-tensile bolts of 8.8, 10.9 and 12.9 and their respective nuts.

Available in steel or stainless steel with narrow or wide bearing surfaces – other materials are available upon request.

Available from M3 – M76 and ¼” – 3” – customised sizes upon request -

Wing Screws and Thumb Screws

Wing Screws and Thumb Screws

This is a type of fastener designed to be tightened and loosened by hand rather than needing tools like screwdrivers or wrenches for installation. They have a wide range of useful applications, especially in parts, materials and builds that do not easily support the use of manual or power tools. These can also be useful solutions in a situation where you may need to remove a component or panel regularly. They can make tasks such as maintenance or cleaning much quicker and easier than having to use a driver to remove fully torqued machine screws, bolts, or rivets.

Wing Screws

Wing screws have a wing-like projection from the head of the screw, ideal for

thumb and forefinger leverage in turning.

Ensures rapid assembly and disassembly using only your hand. Wing screws and other hand fasteners are easy to install and make adjustments simple.

They’re ideal for applications where frequent access is require or where tightness needs to be adjusted regularly.

Available in Stainless Steel from M3 to M10.

Thumb Screws

The head of the thumb screw is knurled to provide extra grip and prevent slippage when tightening and loosening. The head diameter of the screw is large for ease of use and also provides a high degree of rotational accuracy.

Thumb screws are available in a shouldered versions known as knurled thumbscrews.

These are widely used in various applications where frequent access, adjustment, or disassembly is required, such as in the field of electronics, computer hardware, automotive, and machinery. Their convenient design enables users to make quick and tool-free adjustments, making them especially valuable in situations where efficiency and convenience are crucial.

Their main use is for fastening down panels, wiring, lids, safety covers, battery compartments, and any other part or component that might need to be removed and reinstalled frequently. They can be used for securing equipment, such as cameras, microphones, and lighting fixtures to stands or tripods, as well as electronic components, such as circuit boards or cooling fans. Thumb screws are also commonly used in HVAC systems for securing ductwork and in automotive industries for holding components in place.

Thumb screws are easy to use, as they do not require any special tools or equipment. To use a thumb screw, turn it clockwise or counterclockwise by applying pressure with your thumb and fingers until the desired tension is achieved. Twist the screw in a clockwise direction to tighten it and counterclockwise to loosen it. If extra force or precision is required, a pair of pliers or tweezers may be used to grip the head of the screw.