Installation is simple, prepare the specified hole and using a flat punch and appropriate anvil, apply a parallel squeezing force to press the part into the hole. When installing in printed circuit board, broaching nuts are suitable for use in non-plated holes only.

-

Clinch Nuts

The sheet metal surrounding the head cold flows into an undercut thereby making the fastener an integral part of the sheet.

Clinch Nuts can also be used instead of tapped holes for a more durable and stronger connection. Nuts, standoffs and studs can be used where it is not practical, or possible, to insert a fastener on both sides of a case.

For example, in an instance where there is a nut installed on the inside of an enclosure, you wouldn’t be able to hold a wrench to attach the cover, since the cover would interfere.

For the best dimensional accuracy we recommend that all holes in the sheet metal application be punched. To install the fastener into the punched Hole a profiled punch is required. It is essential that the recommended Hole tolerances be observed.

Self-Clinching Nuts provide strong reusable female threads in panels that are too thin to be conventionally tapped. Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst providing a flush finish on the underside of the panel.

Like all self clinching fasteners they are installed using a parallel squeezing force so require access to both sides of the panel.

-

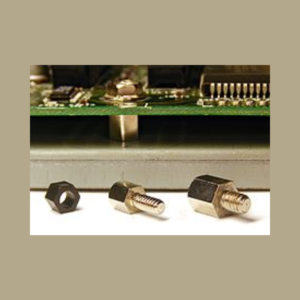

Press Nuts (Broaching Nuts)

Press nuts are used wherever a high degree of joint stability is required in thin-walled sheet metal or plastic parts. They are a very good alternative to nuts that are welded, brazed or welded to the component. Press nut that can obtain a high mounting strength thanks to the knurled portion under the neck.

Portion of the nut under the neck has a unique shape (knurled, grooved) and so a high mounting strength can be obtained.

Post-processing such as rust-proof processing, sputtering treatment for weld-on nuts, etc., not required.Broaching-type fasteners can be used on printed circuit boards as well as on many other types of brittle materials. They are often used on materials composed of glass laminate or epoxy bases. They are also designed for use on materials that are too thin to support adequate threading.

Broaching nuts, also known as PCB nuts due to being commonly applied in printed circuit boards, are designed with a knurled shank that can be pressed into the drilled hole. The shank grips the board with an interference fit by broaching its way into the panel as it is squeezed into the holes.

-

Flush Nuts

If you have a need for an industrial fastener that, after installation, will be completely flush with its surrounding surface, then the self-clinching flush nut should be your fastener of choice.

This type of insert nuts for flush insertion on both sides are flush with the top and bottom of the sheet metal.

These fasteners are ideal for applications where a thin sheet requires load-bearing threads but still must remain smooth, with no protrusions on either surface. This can provide strong threads in places which would be inaccessible for installation after chassis are formed.

Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst providing a flush finish on both sides of the panel. The hexagonal head ensures high axial and torsional strength.

Like all self clinching fasteners they are installed using a parallel squeezing action, so require access to both sides of the panel.

Advantages

- Ease of installation: All that is required to successfully install the nut is a simple parallel press device which can be used to push the flush nut into position.

- Suitable for use in thin metal: Provides a strong attachment in metal as thin as 1.6mm with a FLUSH finish.

- No hole preparation required: Eliminates the need for deburring or refinishing.

- Material suitability: Self-clinching flush nuts can be used in a wide variety of materials, including materials that are not conducive to welding.

- No secondary operations: Eliminates the need for additional tapping after installation.

- Insertion automation: Insertion process may be fully automated, thereby increasing process speed and reducing overall production costs.

- These Type F self-clinching nuts particularly can be installed flush before bending or forming operations get under way without risking potential interference problems that protruding fasteners could cause down the line.

Like all self-clinching fasteners they are installed using a parallel squeezing action, so require access to both sides of the panel.

Flush Nuts are available in various thread sizes, manufactured from 300 series stainless steel and are suitable for installation in ductile steel and aluminium panels with a recommended maximum hardness of 70 HRB

-

Self Clinching Blind Fastener

Self Clinching Blind Fasteners are used in applications requiring closed end threads.

Also known as clinching blind press nuts, they provide an excellent design solution for assemblies where there is a desire to protect the contents from foreign matter.

The blind press nuts can be installed into panels as thin 1.0mm. The configuration of the blind press nuts also limit the mating screw’s penetration into the assembly which can prevent any interference within the design.

This feature prevents any contact with the electronic circuitry in the design.

In contrast to the open version, the closed end self clinching nuts offer the advantage of a longer threaded part. The closed shank end seals the thread against external influences such as dirt, oil, moisture and protects against atmospheric corrosion.

In addition, their use is generally more cost-effective than comparable fasteners with similar sealing properties, which, however, require complicated seals and special assembly procedures.

Advantages

- Provide barrier against foreign matter

- Limits screw penetration thereby protecting internal components

- A sealing effect is achieved

These nuts provide a permanent blind thread in thin metal sheets.

The blind press nuts, along with providing the protection of shielding foreign matter from the design, and the mating screws penetration, they also eliminate the possibility of loose hardware.

The blind fastener encapsulates your threads, typically to prevent any foreign material from entering inside. Protrudes on one side of the sheet metal.

-

Self Clinching Studs

Self-Clinching fasteners provide strong load bearing male or female threads in thin steel and aluminium panels.

Installation is neat and easy.

Simply locate the fastener into a pre-prepared hole and apply a parallel squeezing force to embed the fastener into the panel.

Self-Clinching fasteners work by utilizing a special clinch feature.

When the part is pressed into the hole, the parent material cold-flows into the clinch feature, effectively locking the fastener into the panel, providing excellent torque-out and push-out performance.

Self-Clinching fasteners require a parallel squeezing force to be applied for correct installation.

Equally important is the length of time the force is applied. Sufficient time must be allowed for the cold-flow clinching process to work (this is often referred to as the dwell time when installing on a hydraulic press).

A self clinching stud is designed to become a permanent fixture of the part, component, or device onto which it’s installed. Installation is usually performed during the initial fabrication stage or in final assembly of the metal chassis. Parallel squeezing force is applied in order to secure the stud to the sheet metal panel.

For the best dimensional accuracy and performance, it is recommended that all holes in the sheet metal application be punched.

These externally threaded fasteners become permanently mounted to a metal framework, reducing costs and assembly time by eliminating the necessity for loose hardware and additional installation processes.

Self clinching studs are used for varying purposes, though all varieties are built to withstand high levels of torque, heavy weights, and constant, repeated pull by the attached components.

-

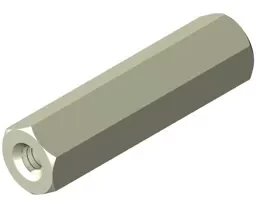

Self Clinch Standoffs

A Self-Clinching Standoff provides an excellent solution for mounting, spacing and stacking of boards and panels.

They provide strong captivated reusable female threads in a spacer format in thin sheets.

Utilising a hexagon head and a clinch feature, this fastener has excellent torque-out, pull-through and push-out characteristics whilst providing a flush finish on the underside of the panel, requiring minimal surface finishing after installation.

They are installed using a parallel squeezing action, so require access to both sides of the panel.

Ease of assembly and quick removal are major reasons to specify Clinch Standoffs. They satisfy many functional and cosmetic requirements.

Threaded standoff bushes are an effective fastening element that serves as a spacer. A time-saving and simple assembly of workpieces, which have to be arranged at a certain distance from each other or parallel to each other, is made possible by this fastener.

They provide protection for fragile circuitry and electrical connections in printed circuit boards (PCBs) and other electrical assemblies. Self clinching standoffs eliminate the need for loose hardware on aftermarket components.

How Self Clinch Standoffs Work

Attached components are stacked on top of each other or distanced from the framework material by a standoff secured to a thin sheet metal chassis. These metal fasteners ensure safe grounding of electrical components and help reduce or eliminate hardware damage that can occur due to vibration and collision.

-

Pilot Pins

Self-Clinching fasteners provide strong load bearing male or female threads in thin steel and aluminium panels.

Installation is neat and easy.

Simply locate the fastener into a pre-prepared hole and apply a parallel squeezing force to embed the fastener into the panel.

Self-Clinching fasteners work by utilizing a special clinch feature.

When the part is pressed into the hole, the parent material cold-flows into the clinch feature, effectively locking the fastener into the panel, providing excellent torque-out and push-out performance.

Self-Clinching fasteners require a parallel squeezing force to be applied for correct installation.

Equally important is the length of time the force is applied. Sufficient time must be allowed for the cold-flow clinching process to work (this is often referred to as the dwell time when installing on a hydraulic press).

Pilot Pins – JC-TPS Pins

Pilot Pins are a type of locating pins that resemble threadless studs. These pilot pins have a rounded profile with a tapered tip.

They assist in aligning components before fastening, ensuring accurate installation.

-

Threaded Standoffs and Spacers

Spacers and Standoffs are two common types of positioning electronic hardware. Look inside an assembled circuit board, and you will be greeted by a bevy of Standoffs and Spacers, because in the world of Electronic Hardware, they are the standard for connecting and mounting circuit boards, panels, doors, and gears providing sturdy support and alignment.

Both are commonly used to properly position parts within an assembly, to reduce component contact, to elevate stacked sections, to ensure enough room for heat to dissipate, and to separate or create space between two objects. These guys are workhorses!

Threaded Standoffs and Spacers

Standoffs are threaded hollow Hex or Round fasteners that separate and position components while also fastening them together. The standoff hardware screws onto bolts or screws by hand. Also called standoff mounts, these fasteners are commonly used to raise one assembly above the other, such as elevating a circuit board above a surface. They can also be used to extend thread options or as an adapter to join male-threaded parts to female-threaded parts (and vice versa).Types:

1) Through Internal Threaded Standoffs.These are Female-Female type also known as hex spacers with internal thread or F-F Spacers.

1) Through Internal Threaded Standoffs.These are Female-Female type also known as hex spacers with internal thread or F-F Spacers. 2) Male-Female (E.T.) StandoffsThese are Male-Female type also known as ET spacers or M-F Spacers.

2) Male-Female (E.T.) StandoffsThese are Male-Female type also known as ET spacers or M-F Spacers.Selection Guide

When designing and choosing a Standoff for your next application, it is easiest to think of standoffs as 3 separate sections; the two threaded ends and the main body. The below guide will help you think through those 3 sections and provide the common information needed for finding the right standoff.

Step 1 – Thread Type

Standoffs are divided into a few different styles and named after the type of threads on each end.

Female-Female Standoffs

These are also referred to as a Threaded Spacer and come with female threads on both ends of the part. This allows for a screw or male standoff to be installed on either side.

In shorter lengths, standoffs will be threaded through the entire part, where longer standoffs are threaded to a minimum thread depth.

Male-Female Standoffs

These have one end with a male thread and the other end has a female thread.

These are excellent for use when stacking circuit boards as each male thread can be installed into the mating part’s female thread.

This quickly reduces the number of fasteners needed in the assembly while also reducing installation time.

Male-Male Standoffs

This has male threads on both ends and are used to connect 2 female threaded components.

These are also commonly utilized as thread adapters to convert a female thread to a male thread.

Male ends can be the same or a different thread for a wider range of applications.

Step 2 – Thread Size

Standoffs are readily available in all common thread sizes, in both inch and metric series. While most commonly found with each end having the same size thread, different thread sizes can be manufactured on specific order.

Step 3 – Body Length

The third part of the standoff once the thread sizes have been determined is the body.

As standoffs are commonly used to separate 2 components, the body of the standoff is what will separate the components.

As each application will require a unique body length, all standoffs come in a wide range of length options.

Parts are machined to a tolerance for a secure and consistent fit.

Custom lengths and tolerances can be manufactured on special order.

Through Internal Threaded Hex Standoff F-F

A hexagonal, mechanical device which has a partial or complete internal thread, used to hold two components at a given distance from each other.

Advantages – Standoffs are usually chosen over spacers when longer sizes are required. Hex standoffs can be installed with a nut-setter or other wrenching device.

Suitable for using with screws at both ends providing a clean finish.

Materials

Brass

Brass is used in making high-quality standoffs. It is conductive, resists corrosion, and is non-magnetic. It is costlier and heavier than Nylon and is usually plated nickel